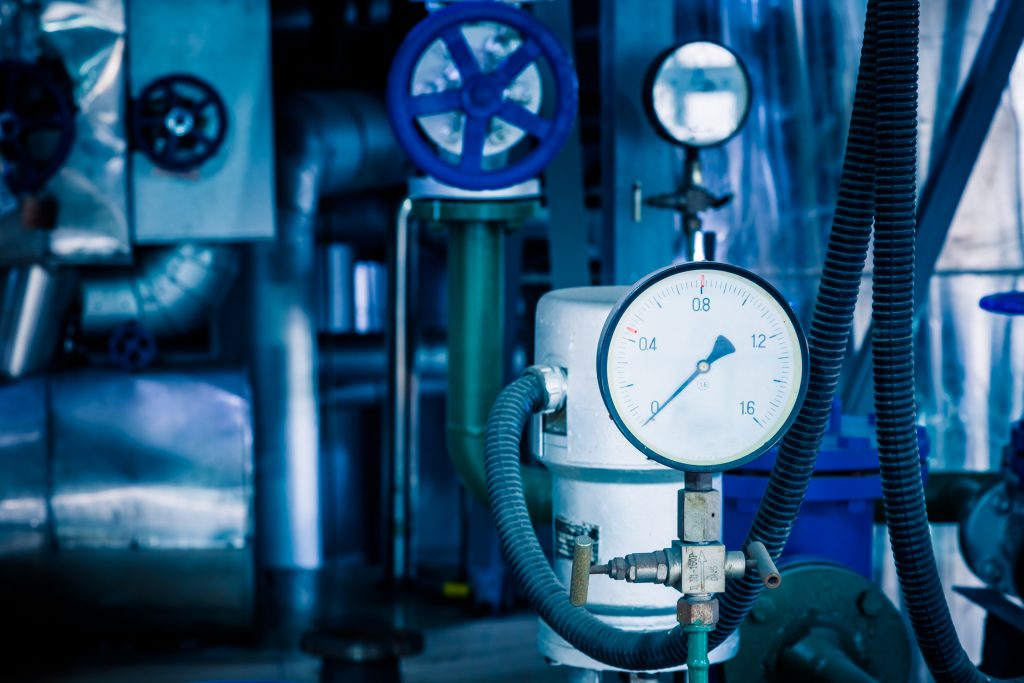

In the world of industrial operations, the importance of reliable, efficient, and durable industrial valves cannot be overstated. Whether you’re managing a chemical plant, water treatment facility, or oil and gas operation, the right industrial valves are crucial for controlling flow, pressure, and temperature. Megalos Ferro Inc., a leader in the supply of high-quality industrial valves, understands the complexities involved in choosing the optimal valve for your application. This comprehensive guide will walk you through the key factors to consider and help you make informed decisions to enhance your operational efficiency.

What Are Industrial Valves?

Industrial valves are devices used to regulate, direct, or control the flow of fluids—liquids, gases, or slurries—within a system. They come in various types, each designed for specific functions and operating conditions. From simple shut-off valves to complex control valves, the right choice depends on numerous factors, including fluid characteristics, pressure, temperature, and system requirements.

Importance of Choosing the Correct Industrial Valves

Selecting the appropriate industrial valves ensures safety, efficiency, and longevity of your equipment. Properly specified valves reduce downtime, maintenance costs, and the risk of leaks or failures, ultimately leading to smoother operations and cost savings.

Key Factors to Consider When Choosing Industrial Valves

Type of Industrial Valve

The first step in selecting the right industrial valves is understanding the different types available:

- Ball Valves: Ideal for quick shut-off applications, offering tight sealing and ease of operation.

- Butterfly Valves: Suitable for large volume flow control with quick operation and minimal space requirements.

- Gate Valves: Used for on/off control in large pipes, providing minimal pressure drop.

- Globe Valves: Suitable for throttling flow and precise regulation.

- Check Valves: Prevent backflow, ensuring system integrity.

- Control Valves: Used for precise regulation of flow, pressure, or temperature.

Choosing the right type depends on your application’s specific needs, such as flow control precision, pressure conditions, and flow rates.

Material Compatibility

Industrial valves must withstand the chemical, temperature, and pressure conditions of your system. Common materials include:

- Stainless Steel: Corrosion-resistant, suitable for corrosive fluids.

- Brass and Bronze: Good for water and non-corrosive fluids.

- Cast Iron and Ductile Iron: Cost-effective options for water and air systems.

- Alloys (e.g., Monel, Inconel): For highly corrosive or high-temperature applications.

Megalos Ferro Inc. offers a wide range of industrial valves crafted from durable materials tailored to your specific process requirements.

Pressure and Temperature Ratings

Ensure the industrial valves you select can handle the maximum operating pressure and temperature of your system. Using valves outside their rated conditions can lead to failures, leaks, or safety hazards.

Flow Rate and Size

The flow rate dictates the size of the industrial valves needed. Oversized or undersized valves can cause inefficiencies, pressure drops, or flow restrictions. Proper sizing is vital for optimal performance.

Actuation Method

Valves can be operated manually or automatically via actuators. Consider factors like:

- Manual Operation: Suitable for infrequent control.

- Electric Actuators: Ideal for remote or precise control.

- Pneumatic or Hydraulic Actuators: Suitable for fast and automated operations.

Megalos Ferro Inc. provides a variety of actuation options to match your operational needs.

Control and Automation Needs

If your system requires automation, selecting industrial valves compatible with your control systems (like SCADA or DCS) is essential. Control valves with integrated positioners or sensors facilitate seamless integration.

Maintenance and Reliability

Choose industrial valves that are known for durability and ease of maintenance. Valve design, accessibility, and availability of spare parts influence long-term operational costs.

Certification and Standards

Ensure the industrial valves comply with relevant industry standards such as API, ANSI, ASME, or ISO. This guarantees quality, safety, and compatibility with regulatory requirements.

Why Choose Megalos Ferro Inc. for Industrial Valves?

As a reputable supplier, Megalos Ferro Inc. offers an extensive selection of industrial valves tailored to various industries and applications. Our commitment to quality, innovation, and customer satisfaction makes us your ideal partner for sourcing reliable industrial valves.

Our Product Range

- Ball valves

- Butterfly valves

- Gate valves

- Globe valves

- Check valves

- Control valves

All our industrial valves are manufactured following strict standards, ensuring durability and performance.

Custom Solutions

We understand that each application has unique requirements. Megalos Ferro Inc. provides customized industrial valve solutions, including special materials, sizes, and actuation options.

Technical Support and Expertise

Our team of experts offers guidance on selecting the right industrial valves, ensuring you achieve optimal system performance and safety.

Case Study: Industrial Valves in a Chemical Processing Plant

A chemical processing plant faced frequent valve failures, leading to costly downtime. After consulting with Megalos Ferro Inc., they upgraded their system with corrosion-resistant stainless steel industrial valves tailored for high-pressure, corrosive fluids. The result was improved process reliability, reduced maintenance costs, and enhanced safety.

Choosing the right industrial valves is a critical decision that impacts the safety, efficiency, and longevity of your industrial systems. By considering factors such as valve type, material compatibility, pressure and temperature ratings, flow requirements, and automation needs, you can ensure optimal performance. Partnering with experienced suppliers like Megalos Ferro Inc. ensures access to high-quality industrial valves and expert support to meet your specific application demands.

Investing time and resources into selecting the appropriate industrial valves today will pay dividends through smoother operations, reduced downtime, and increased safety in your industrial processes.

Contact Megalos Ferro Inc.

Ready to upgrade or specify industrial valves for your application? Contact Megalos Ferro Inc. today for expert advice, customized solutions, and a comprehensive range of industrial valves designed to meet your needs.

read more