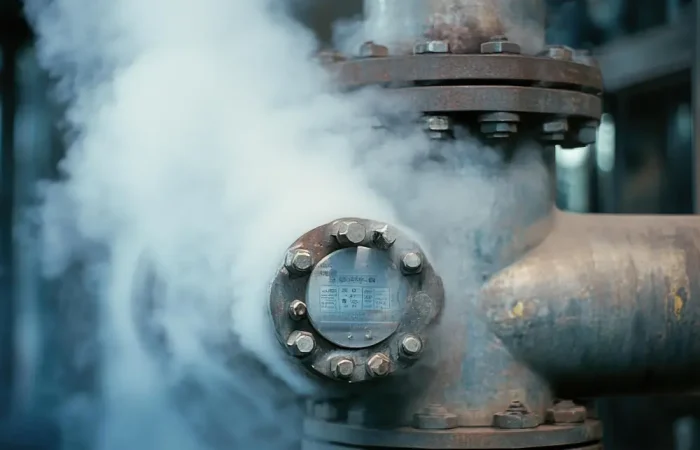

The Philippines faces an average of 20 typhoons every year, bringing heavy rains, floods, rapid pump shutdowns, and unstable water pressures across facilities. From municipal water systems to manufacturing plants and power generation sites, the combination of sudden pressure changes and pipeline stress makes storm season a critical threat to industrial operations.

One of the most commonly overlooked risks during typhoons is pressure surge—also known as water hammer. This occurs when the flow inside pipelines changes abruptly, often due to pump shutdowns, valve mis-operation, or emergency isolation events. These spikes can cause:

- Valve failure

- Pipeline ruptures

- Joint blowouts

- Flooding inside the facility

- Costly downtime and emergency repair expenses

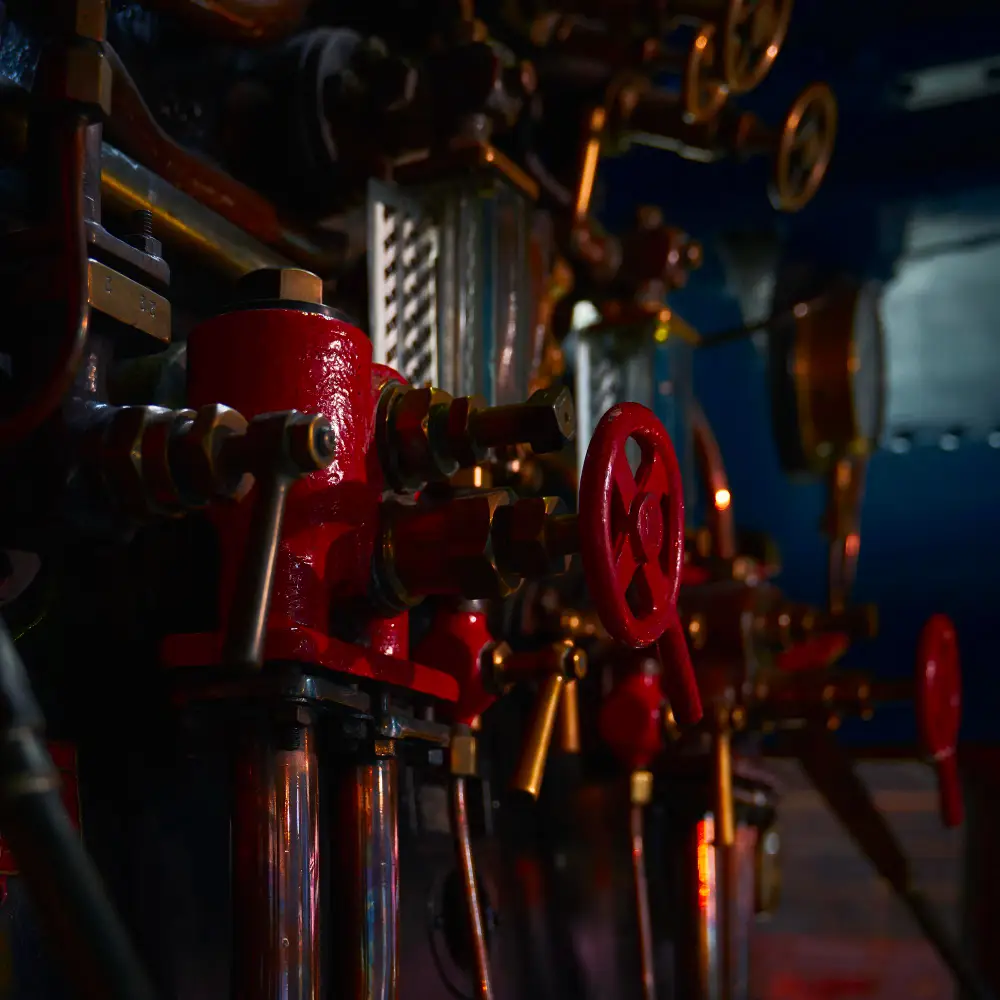

In industrial environments, the right Industrial Valves can prevent this damage and ensure stability even during extreme weather.

What Causes Pressure Spikes During Typhoons?

During storms, plants often experience:

| Situation | Impact |

| Sudden power outage | Pumps shut down → flow stops instantly → surge pressure increases |

| Rapid valve closure | Water momentum has nowhere to go → internal shockwaves form |

| Flooding in pumping stations | Equipment speed is affected → unstable flow and pressure shifts |

| System restart after storm | Rapid re-pressurization can crack pipes and fittings |

These conditions stress valves and pipelines beyond normal operating loads, especially in older or poorly maintained systems.

How the Right Industrial Valves Prevent Surge Damage

1. Pressure Relief Valves (PRVs)

These valves release excess pressure automatically when a spike occurs.

They protect the system from over-pressurization damage.

2. Surge Anticipation Valves

Designed specifically for storm and blackout conditions, these valves sense rapid pressure changes and open before damaging surges occur.

This is especially important in:

- Water distribution systems

- Industrial pumping stations

- Power plant cooling pipelines

3. Slow-Closing Check Valves

During pump shutdown, backflow can slam pipelines with reverse pressure.

A slow-closing check valve prevents this by:

- Controlling closure speed smoothly

- Eliminating the “slam” effect that causes shockwaves

4. Air Release & Vacuum Valves

These valves remove trapped air and prevent vacuum collapse when pressure drops.

Air pockets inside pipelines often trigger:

- Cavitation

- Pipe vibration

- Joint stress

Air release valves solve this problem.

Why Material & Build Quality Matter During Typhoons

Floodwater and humidity accelerate:

- Corrosion

- Seal failures

- Actuator malfunction

Typhoon-ready Industrial Valves must feature:

| Specification | Advantage |

| Corrosion-resistant bodies (Stainless Steel, Ductile Iron, Bronze) | Longer life in wet environments |

| High-integrity gaskets and seats | Prevent leakage and pressure loss |

| Moisture-protected actuators and gearboxes | Maintain function even when wet |

| Compliance with AWWA / ISO / API standards | Ensures safety & reliable operation |

Megalos Ferro Inc. supplies industrial-grade valves engineered for harsh Philippine conditions, including coastal and flood-prone zones.

Pre- & Post-Typhoon Valve Inspection Checklist

Before Typhoon

- Confirm all surge protection valves are operational

- Check actuator seals and lubrication

- Verify pump sequence controls for shutdown and restart

- Ensure manual overrides are accessible

After Typhoon

- Inspect valves for sediment blockage

- Test pressure relief and check valve functions

- Look for corrosion on seals, stems, and fasteners

- Document issues for scheduled service or replacement

Proactive inspection helps prevent catastrophic failure during the next storm.

How Megalos Ferro Inc. Helps Industrial Facilities Stay Storm-Ready

Megalos Ferro Inc. provides:

✅ Industrial Valves designed for high-pressure & storm surge protection

✅ Technical guidance for valve selection based on plant conditions

✅ Support for maintenance teams in inspection and replacement planning

✅ Reliable sourcing from globally certified valve manufacturers

Our solutions are built for real Philippine environments, where typhoons are not the exception — they’re expected.

Pressure surges during typhoons can put your entire pipeline system at risk. The right Industrial Valves, correctly installed and maintained, protect your facility from:

- Sudden pressure spikes

- Equipment damage

- Service interruption

- Unnecessary repair costs

Investing in surge-protection valves is not just about safety — it is business continuity.

Don’t wait for surge damage to happen.

Upgrade to typhoon-ready Industrial Valves now.

➡️ Request a quotation today.