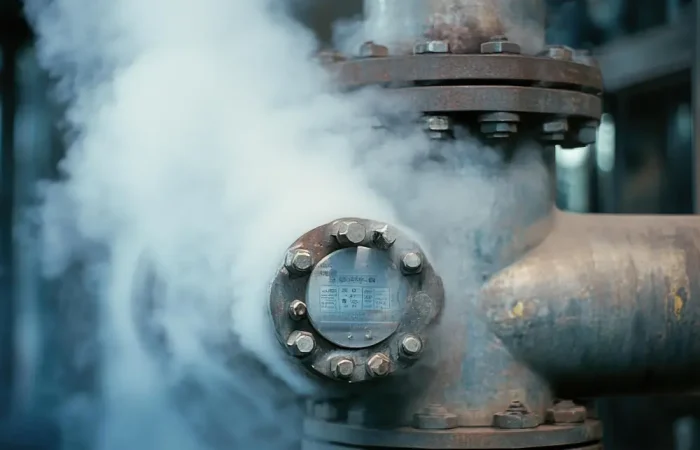

The Philippines sits within the Pacific Ring of Fire, a region prone to frequent and sometimes devastating earthquakes. As urban areas continue to expand, thousands of older buildings face a growing risk of collapse during strong seismic events. One of the most effective ways to address this challenge is through retrofitting with steel, particularly with materials like Nippon Steel Japan Pipe, known for its superior strength, reliability, and durability.

In this article, we’ll explore how steel retrofitting works, why Nippon Steel Japan Pipe is the preferred choice, and how Megalos Ferro Inc. plays a vital role in providing high-quality steel solutions that safeguard lives and infrastructures.

Understanding the Need for Structural Retrofitting

Structural retrofitting is the process of strengthening existing buildings to meet current safety and performance standards. It’s a crucial step for structures that were built before modern seismic codes were introduced.

Older buildings often have weaker frames or lack the flexibility to absorb ground motion during earthquakes. Without intervention, these structures could experience severe damage—or worse, collapse. Retrofitting ensures they can withstand lateral loads, vibrations, and ground shifts, effectively extending their lifespan and improving occupant safety.

Why Steel is the Best Material for Retrofitting

Steel remains one of the top materials for retrofitting due to its high strength-to-weight ratio, ductility, and resilience. Unlike concrete or wood, steel can deform under pressure without cracking, allowing structures to absorb seismic forces and prevent catastrophic failure.

Some key benefits of steel retrofitting include:

- Enhanced flexibility: Steel connections and braces allow controlled movement during quakes.

- Lightweight reinforcement: Adds minimal load to existing foundations.

- Speed of installation: Prefabricated steel components simplify retrofitting projects.

- Long-term durability: Resistant to corrosion and fatigue when using premium-grade steel.

When it comes to reliability and performance, Nippon Steel Japan Pipe stands as a trusted choice for structural retrofits.

Nippon Steel Japan Pipe: The Standard for Quality and Strength

Nippon Steel Japan Pipe is globally recognized for its superior metallurgical properties and consistent performance under extreme conditions. Manufactured with advanced Japanese engineering, these pipes are designed to deliver exceptional tensile strength and resistance against stress, corrosion, and temperature changes.

Here’s why engineers and contractors prefer Nippon Steel Japan Pipe for retrofitting projects:

- High Yield Strength: Ideal for structural bracing and reinforcement under seismic load.

- Excellent Ductility: Maintains shape and function even under repeated stress cycles.

- Superior Corrosion Resistance: Ensures long-term performance even in humid or coastal environments.

- Precision Manufacturing: Each pipe meets international quality standards for construction safety.

- Sustainability: Produced with environmentally responsible methods aligned with global green initiatives.

With these advantages, Nippon Steel Japan Pipe helps ensure that retrofitted structures achieve modern safety standards and remain resilient for decades.

How Megalos Ferro Inc. Supports Safer Construction with Nippon Steel Japan Pipe

As one of the leading steel distributors in the Philippines, Megalos Ferro Inc. supplies premium Nippon Steel Japan Pipe to engineers, contractors, and builders across various industries. The company’s mission is to provide top-quality steel materials that empower construction professionals to build safer and more reliable infrastructures.

Through a strong partnership with trusted global brands, Megalos Ferro Inc. ensures that every steel product meets international certifications for quality and safety. Their technical team also assists clients in selecting the right steel specifications for their retrofitting projects, guaranteeing both efficiency and cost-effectiveness.

By integrating Nippon Steel Japan Pipe into retrofitting projects, Megalos Ferro Inc. helps reinforce critical structures such as:

- Old commercial buildings in urban centers

- Schools and hospitals built before modern building codes

- Bridges and public facilities requiring seismic upgrades

- Industrial plants in earthquake-prone regions

Step-by-Step: How Steel Retrofitting Works

The process of retrofitting with Nippon Steel Japan Pipe involves several technical steps, each designed to ensure the structure’s stability and compliance with safety standards:

- Structural Assessment: Engineers inspect the building’s integrity and identify weak points.

- Design and Planning: Customized retrofitting plans are created, integrating steel components strategically.

- Installation of Reinforcements: Steel braces, frames, and pipes are installed to strengthen columns and beams.

- Testing and Verification: Engineers conduct load tests and simulations to confirm the building’s improved resistance.

- Final Evaluation: The retrofitted structure is re-certified to meet current earthquake resilience codes.

Using Nippon Steel Japan Pipe throughout this process ensures that every reinforcement is reliable, precise, and capable of performing under intense seismic activity.

Real-World Benefits of Retrofitting Old Structures

Investing in steel retrofitting delivers both immediate and long-term benefits, including:

- Increased safety for occupants during earthquakes

- Reduced repair costs compared to post-disaster reconstruction

- Extended service life of existing buildings

- Compliance with local building codes and insurance requirements

- Enhanced property value for commercial and residential properties

By choosing Nippon Steel Japan Pipe, property owners and developers gain confidence that their buildings can withstand natural disasters with minimal risk.

Building a Resilient Future with Megalos Ferro Inc.

In today’s era of heightened environmental risks, building resilience is no longer optional—it’s essential. Megalos Ferro Inc. champions this vision by supplying reliable materials like Nippon Steel Japan Pipe, ensuring that every retrofitting project contributes to a safer, more sustainable Philippines.

Whether upgrading aging infrastructures or reinforcing modern facilities, Megalos Ferro Inc. remains a trusted partner in construction safety and innovation.

Retrofitting is one of the smartest investments for property owners seeking to future-proof their buildings against earthquakes. Through the use of Nippon Steel Japan Pipe, structures can achieve unmatched durability, strength, and resilience.

With the expertise and quality assurance of Megalos Ferro Inc., every project benefits from world-class steel solutions engineered to protect lives and communities. When it comes to earthquake preparedness, retrofitting with Nippon Steel Japan Pipe is more than just an upgrade—it’s a commitment to safety and sustainability.