Tackling the Philippines’ Flood Challenges

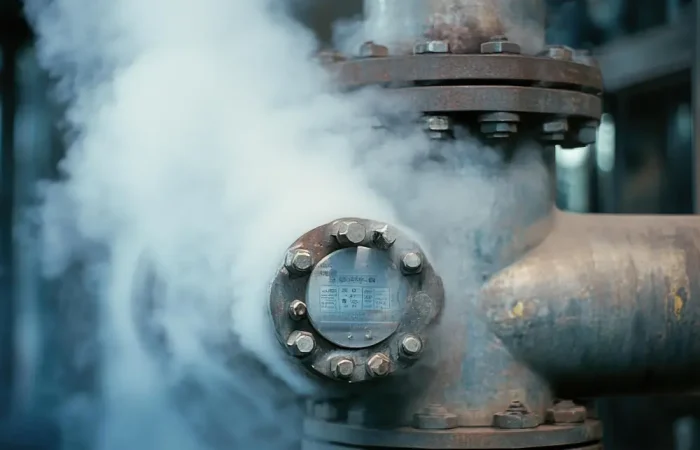

Flooding has long been one of the most persistent problems in the Philippines. With more than 20 typhoons hitting the country annually and heavy monsoon rains affecting low-lying areas, effective water management infrastructure has never been more crucial. The government’s flood-control programs — from urban drainage upgrades in Metro Manila to river dike improvements in Mindanao — highlight the urgent need for durable, high-capacity piping systems that can withstand extreme conditions.

As climate change continues to intensify weather events, Spiral Welded Pipes are emerging as an essential component in building flood-resilient systems across the nation.

Why Infrastructure Matters Now

Recent years have seen a strong push from the Department of Public Works and Highways (DPWH) and local government units to expand drainage and flood mitigation projects. However, these initiatives face several hurdles — from budget constraints and procurement delays to inconsistent material quality.

Reports from publications such as East Asia Forum and The Manila Times have pointed out that the long-term success of infrastructure programs relies not only on funding but on the quality and reliability of materials used. Substandard pipes or poor installation can lead to costly project failures, making the case for tested, certified, and locally available Spiral Welded Pipes even stronger.

What Is a Spiral Welded Pipe?

A Spiral Welded Pipe is manufactured by spirally forming a steel coil into a cylindrical shape and welding the seams along the spiral. This design provides uniform strength throughout the pipe’s structure. Compared to straight-seam or longitudinal welded pipes, spiral welded pipes can be produced in larger diameters and longer lengths, making them ideal for large-scale water conveyance and drainage applications.

Key advantages include:

- High strength and flexibility — can handle internal and external pressures effectively.

- Cost efficiency — lower production costs per meter due to continuous welding.

- Versatility — suitable for drainage, storm-water channels, irrigation, and culverts.

- Ease of transport and installation — available in longer lengths with minimal joints.

Spiral Welded Pipes in Flood-Control Infrastructure

Flood-control systems rely on efficient water flow management — from collecting stormwater to channeling it safely away from communities. Spiral Welded Pipes play a crucial role in multiple applications:

- Drainage Systems: Carry rainwater from streets and residential zones into retention ponds or waterways.

- Culverts and Storm-Water Channels: Installed under roads and bridges to allow smooth water passage.

- River Embankments and Outfalls: Used to discharge water safely into rivers or seas while preventing erosion.

- Irrigation and Water Diversion Projects: Support both agricultural and urban development efforts.

Their structural integrity and large-diameter capabilities make them indispensable for modern flood-control projects across the Philippines.

The Philippine Context: Real-World Applications

In Metro Manila, flood-control projects such as the Blumentritt Interceptor Catchment Area and the Pampanga River Basin Project rely heavily on robust water channels and large pipes to manage stormwater surges. Similarly, Mindanao’s river basins — including the Agusan and Pulangi — face annual flooding, demanding durable and large-capacity pipes to handle unpredictable water volumes.

Spiral Welded Pipes are also vital for industrial zones and new township developments in areas like Davao, Iloilo, and Bulacan, where proper drainage is a key factor in sustainable urban planning.

Quality and Supply Chain Considerations

One of the biggest threats to public infrastructure projects is the use of substandard materials or “ghost” project supplies. The Manila Times has underscored the importance of transparent procurement and compliance with Philippine National Standards (PNS) and international ISO certifications for steel products.

By working with a reliable supplier like Megalos Ferro Inc., project developers can ensure:

- Certified quality assurance and product traceability

- Sustainable sourcing and on-time delivery

- Technical assistance for pipe selection and specifications

- After-sales support for long-term project success

How Megalos Ferro Inc. Supports Philippine Infrastructure

At Megalos Ferro Inc., we specialize in providing high-quality Spiral Welded Pipes that meet the demands of flood-control, water management, and industrial applications nationwide.

Our commitment includes:

- Locally available inventory to minimize lead time

- Custom fabrication to match project specifications

- Partnerships with engineering firms for design and implementation support

- Adherence to DPWH and international standards

Megalos Ferro Inc. serves as a trusted steel solutions provider to government projects, private developers, and contractors working toward a flood-resilient Philippines.

Building Resilient Infrastructure with the Right Materials

As the Philippines continues to face stronger typhoons and heavier rains, infrastructure resilience has become a national priority. Investing in high-quality materials such as Spiral Welded Pipes is not just a technical decision — it’s a long-term safeguard for communities and investments.

With Megalos Ferro Inc. as your steel partner, you can be confident that every project is built on strength, reliability, and integrity — helping shape a safer, flood-ready Philippines.