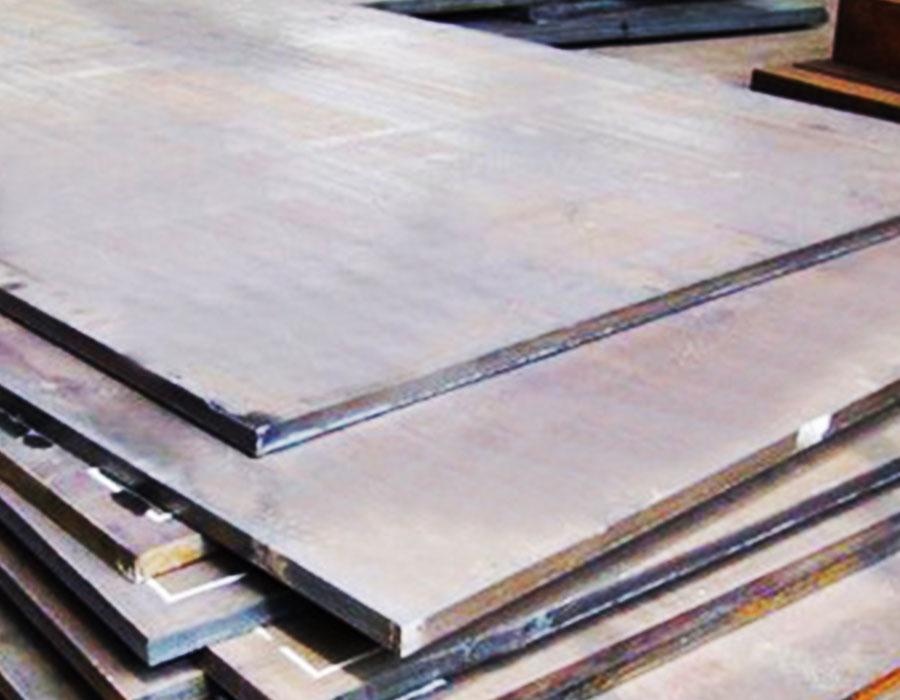

STEEL PLATE

Steel Plate, or structural steel is simply steel sheet material that can be customarily cut and welded to develop a more elaborate product. It is made by compressing multiple steel layers together into one; forming a plate of steel.

Applications for Steel Plate are based acutely on the specifics of the project. This simply means that certain grades are more appropriate to particular tasks than others.

As high-temperature steel is rolled into sheets, the steel gains strength. Layer upon layer of steel is compressed and forged into a single piece of steel until the proper, final dimensions are achieved. As the flat steel sheet cools, it hardens into a usable piece of steel. The type of steel that is created is dependent upon which ingredients are used to create the molten steel.

Steel Plate Applications:

- Structural and Building Construction, Bridge Construction, Tanks, Pressure Vessel, Boiler and Heat Exchangers, Steel Supports, Steel Fabrications, Ship Building

Steel Grades:

- All grade range for Carbon Steel, Mild Steel, Boiler Plate, Tanks, Ship Building, High Strength, Low-Alloy, we also have all range of Stainless Plates.

Available Sizes:

- Thickness- 2.0mm to 250.0mm , Width- 1,200mm to 3,500mm, Length- 4,000mm to 12,000mm

COMMON STEEL GRADES, CODES & SPECIFICATION

| A36 | Carbon Steel Structural |

| SS400 | Carbon Steel Structural (ASTM A36 Equivalent) |

| Q235B | Carbon Steel Structural ( ASTM A36 Equivalent) |

| S275 | Carbon Steel Structural ( ASTM A36 Equivalent) |

| Q345B | Carbon Steel Structural, Higher grade material |

| ASTM A131 | Structural Steel for Ships |

| ASTM A242 | High-Strength Low-alloy Structural Steel |

| ASTM A709 | Carbon and High-strength Low-alloy steel for Bridge |

| ASTM A285 | Pressure Vessel Plates, Carbon Steel, Low & Intermediate Tensile Strength |

| ASTM A516 | Pressure vessel Plates, Carbon Steel, Moderate ^ low Temperature service |

| ASTM A537 | Pressure Vessel Plates, Heat-Treated, Carbon Manganese Silicon Steel |

| ASTM A572 | Structural Carbon Steel Plates of Improved Toughness |

| ASTM A662 | Quenced and Tempered Carbon and High Strength Low-Alloy Structural |

| ASTM A737 | Pressure Vessel Plates, High Strength, Low alloy steel |

| ASTM A662 | Quenced and Tempered Carbon and High Strength Low-Alloy Structural |

| ASTM A737 | Pressure Vessel Plates, High Strength, Low alloy steel |

| ASTM A240 | Stainless Steel |

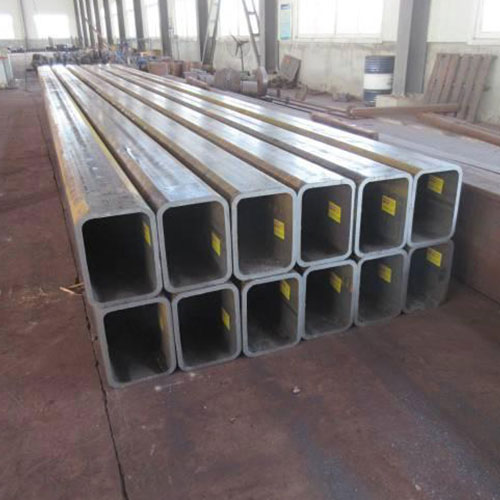

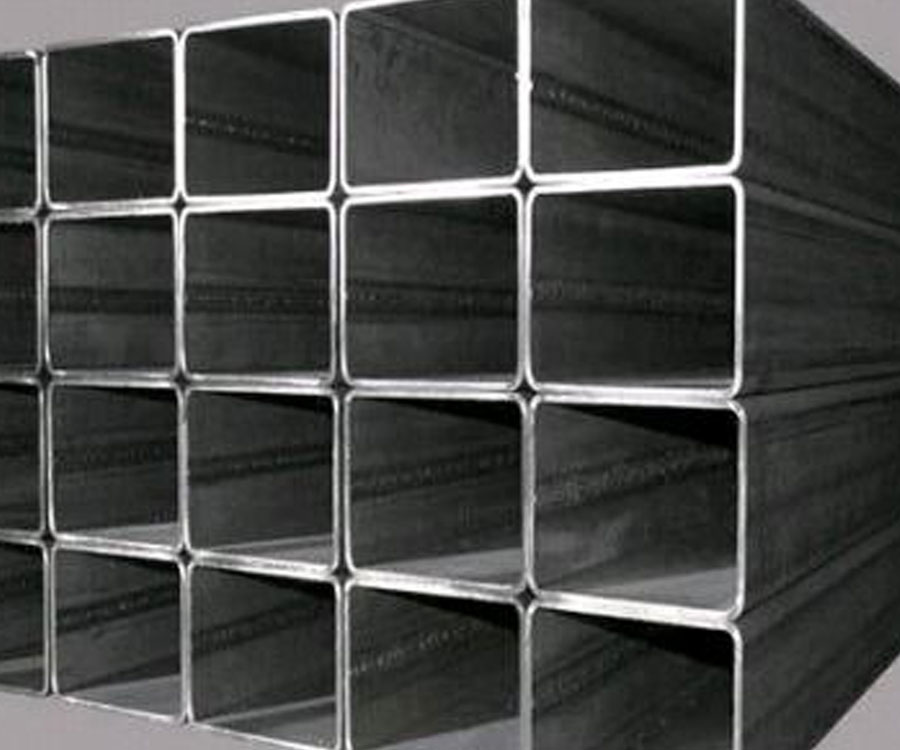

SQUARE TUBE AND RECTANGULAR TUBE

Steel Square Tube and Steel Rectangular Tube products are constructed from hot rolled metal coils that are hollowed out to create their tubular shape. These products are also low in cost and offer a greater strength-to-weight ratio than other types of shaped metal products. In addition, they are regularly utilized throughout the world for their outstanding strength and rigidity.

Steel Square Tube and Rectangular Tube Applications:

- Steel Square Tube and Steel Rectangular Tube products are specifically designed to add additional strength to a project while also concealing wires, pipes and other types of moving parts. Since steel square and rectangle tubes can be easily welded, punched, formed and drilled, they provide a lightweight alternative to other types of steel products, such as wide flange steel and I-beams. Some of the applications that regularly utilize steel rectangular tube and steel square tube, include: Steel Structure, General Fabrication, Transportation Equipment, Manufacturing Structure, Steel Frames, Machine and Equipment Supports, Pipe Supports.

- The construction and engineering industries use hollow structural sections (HSS) term. HSS is a form of steel tubing and is commonly circular, square or rectangular. In the UK the term HSS is not used. Instead the basic shapes are named CHS (circular), SHS (square) and RHS (rectangular).

- Rectangular HSS are commonly used in welded steel frames which are subjected to loading from different directions. Square and circular HSS are often used as columns.

Common Steel Grades:

- ASTM A36, SS400, Q235B, Q345B, ASTM A500 … AND MANY OTHERS!

Available Sizes:

- Wall Thickness- 1.0mm to 50.0mm , Width- 12mm to 600mm, Height- 12mm to 600mm, Length- 4,000mm to 12,000mm

CARBON STEEL PIPES

A carbon steel pipe is a tubular section or hollow cylinder, usually but not necessarily of circular cross-section, used mainly to convey substances which can flow — liquid and gases (fluids), slurries, powders, masses of small solids. It can also be used as steel structure and supports. Our Pipes are available as Pre-Painted, Galvanized or GI Pipe, Bare (not coated), or even with Special Coating and Lining.

Common Steel Grades:

- Most commonly used specs are ASME / ASTM A106 Grades A B or C, API 5L Gr.B SA/ASTM A53-B; SGP; ASTM A333Gr.6/3; APL 5L X42, 52, 60, 65, 70; ASTM A139 (Spiral Pipe); ASTM 795, and MANY OTHERS.

Types of Pipe by Construction:

- Seamless Pipe, ERW Pipe, LSAW Pipe (Straight Weld Pipe), SSAW Pipe (Spiral Welded Pipe)

Carbon Steel Seamless Pipe (SMLS Pipe)

- Seamless (SMLS) pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable, Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

Carbon Steel Welded Pipe

- Welded Pipe is manufactured by rolling metal and then welding it longitudinally across it’s length, therefore welded pipes have a welded joint in it’s cross section. it can be ERW, EFW, LSAW, SSAW

Carbon Steel Pipe Origin

- Carbon Steel Pipe Origin We have brands of and from Sumitomo Pipes Japan, Nippon Pipes Japan, JFE Pipes Japan, Hyundai Pipe Korea, SEAH Pipe Korea, Several from China, Many others from Europe, and our own Brand.

COMMON PIPE SPECIFICATIONS & CODE

| ASTM or API Designation | Title |

| ASTM A 53 | Black and Hot-Dipped, Zinc-Coated, Welded and Seamless Steel Pipe |

| ASTM A 106 | Seamless Carbon Steel Pipe for High-Temperature Service |

| ASTM A 120 | Black and Hot-Dipped Zinc-Coated (Galvanized) Welded and Seamless Steel Pipe for Ordinary Uses |

| ASTM A 134 | Electric-Fusion (Arc)-Welded Steel Pipe (sizes NPS 16 and Over) |

| ASTM A 135 | Electric-Resistance-Welded Steel Pipe |

| ASTM A 139 | Electric-Fusion (Arc)-Welded Steel Pipe (NPS 4 and Over) |

| ASTM A 211 | Spiral-Welded Steel or Iron Pipe |

| ASTM A 312 | Seamless and Welded Austenitic Stainless Steel Pipes |

| ASTM A 333 | Seamless and Welded Steel Pipe for Low-Temperature Service |

| ASTM A 335 | Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service |

| ASTM A 358 | Electric Fusion-Welded Austenitic Chromium-Nickel Alloy Steel Pipe for High Temperature Service |

| ASTM A 369 | Carbon and Ferritic Alloy Steel Forged and Bored Pipe for High-Temperature Service |

| ASTM A 376 | Seamless Austenitic Steel Pipe for High-Temperature Central-Station Service |

| ASTM A 381 | Metal-Arc-Welded Steel Pipe for Use With High-Pressure Transmission Systems |

| ASTM A 405 | Seamless Ferritic Alloy-Steel Pipe Specifically Heat Treated for High-Temperature Service |

| ASTM A 409 | Welded Large Diameter Austenitic Steel Pipe for Corrosive or High-Temperature Service |

| ASTM A 430 | Austenitic Steel Forged and Bored Pipe for High-Temperature Service |

| ASTM A 523 | Plain End Seamless and Electric-Resistance-Welded Steel Pipe for High-Pressure Pipe-type Cable Circuits |

| ASTM A 524 | Seamless Carbon Steel Pipe for Atmospheric and Lower Temperatures |

| ASTM A 530 | General Requirements for Specialized Carbon and Alloy Steel Pipe |

| ASTM A 671 | Electric-Fusion-Welded Steel Pipe for Atmospheric and Lower Temperatures |

| ASTM A 672 | Electric-Fusion-Welded Steel Pipe for High-Pressure Service at Moderate Temperatures |

| ASTM A 691 | Carbon and Alloy Steel Pipe, Electric-Fusion-Welded for High-Pressure Service at High Temperatures |

| ASTM A 714 | High-Strength Low-Alloy Welded and Seamless Steel Pipe |

| ASTM A 731 | Seamless, Welded Ferritic, and Martensitic Stainless Steel Pipe |

| ASTM A 790 | Seamless and Welded Ferritic/Austenitic Stainless Steel Pipe |

| ASTM A 795 | Black and Hot-Dipped Zinc-Coated (Galvanized) Welded and Seamless Steel Pipe for Fire Protection Use |

| API 5L | Line Pipe |

PIPE FITTINGS AND FLANGES

Pipe Fittings

Pipe Fittings are used in pipe plumbing systems to connect straight pipe or tubing sections, to adapt to different sizes or shapes, and for other purposes, such as regulating or measuring fluid flow. Piping or tubing are usually (but not always) inserted into fittings to make connections. To avoid confusion, connections are conventionally assigned a gender of male or female, respectively abbreviated as “M” or “F”. An example of this is a “3/4 inch female adapter NPT,” which would have a corresponding male connection of the same size and thread standard (in this case, NPT).

While there are hundreds of specialized fittings manufactured, some common types of fittings are used widely in piping and plumbing systems.

Elbow

An elbow is a pipe fitting installed between two lengths of pipe or tubing to allow a change of direction, usually a 90° or 45° angle, though 22.5° elbows are also made. The ends may be machined for butt welding, threaded (usually female), or socketed, etc. When the two ends differ in size, the fitting is called a reducing elbow or reducer elbow.

Coupling

A coupling connects two pipes to each other. If the size of the pipe is not the same, the fitting may be called a reducing coupling or reducer, or an adapter. By convention, the term “expander” is not generally used for a coupler that increases pipe size; instead the term “reducer” is used.

Reducer

A reducer allows for a change in pipe size to meet hydraulic flow requirements of the system, or to adapt to existing piping of a different size. Reducers are usually concentric but eccentric reducers are used when required to maintain the same top- or bottom-of-pipe level.

Tee

A tee is the most common pipe fitting. It is available with all female thread sockets, all solvent weld sockets, or with opposed solvent weld sockets and a side outlet with female threads. It is used to either combine or split a fluid flow. It is a type of pipe fitting which is T-shaped having two outlets, at 90° to the connection to the main line. It is a short piece of pipe with a lateral outlet. A tee is used for connecting pipes of different diameters or for changing the direction of pipe runs.

Flange

Flanges are generally used when there is a connection to valves, in-line instruments and/or connection to equipment nozzles is required. Flange fittings generally involve pressing two surfaces to be joined tightly together, by means of threaded bolts, wedges, clamps, or other means of applying high compressive forces.

Flanges are designed to the following pressure ratings: 150 lbs, 300 lbs, 400 lbs, 600 lbs, 900 lbs,1500 lbs and 2500 lbs or 10Bar, 15Bar, 25Bar, 40Bar, 64Bar, 100Bar and 150Bar. Various types of flanges are available depending upon the type of their constructional features.

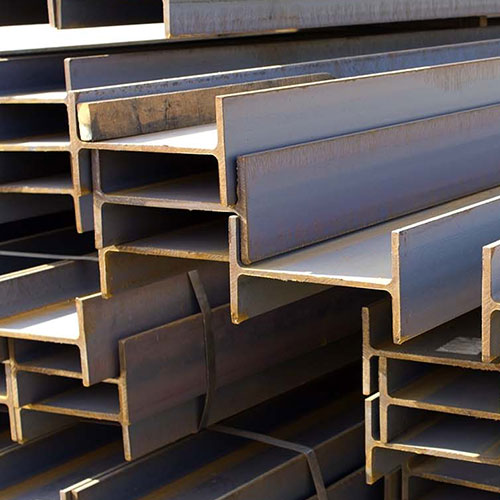

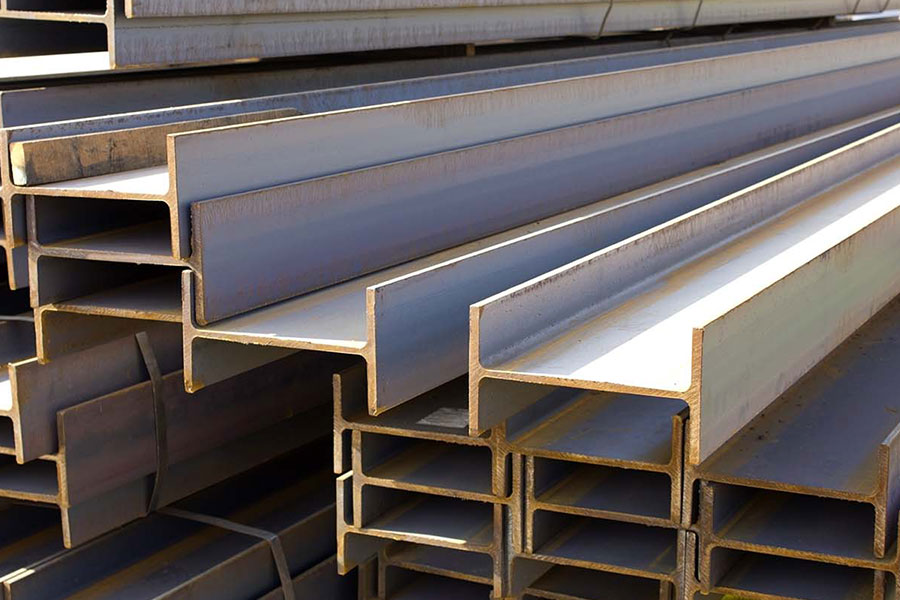

STEEL BEAM AND CHANNEL

A steel beam is a structural steel product that is made to support heavy loads. Steel beams come in different sizes and types, hence their different applications in the construction of structures and buildings. The specifications of a structure determine the geometry, size and shape of beams. These beams can be straight or curved.

Common Steel Grades:

- ASTM A36, SS400, Q235B, Q345B, SJ235, ASTM 572 … AND MANY OTHERS!

Types of Beams based on cross sections:

- I-Beam: This kind of beam is also known as the Standard American Beam or junior beam. It has an I-Cross section.

- T-Beam: As suggested by the name, this beam has a T cross section.

- Channels: Also known as C Beams or C-Channel, these beams have a C cross section.

- Wide Flange Beams: These are also known as H Beams or W Beams. They have flanges that are not tapered and are wider than standard I beams.

STAINLESS PIPES

Stainless Steel is a versatile material comprised of a steel alloy and a small percentage of chromium — the addition of chromium adds to the material’s corrosion resistance, a trait that earned stainless steel its name. Because stainless steel is also low-maintenance, oxidation resistant, and doesn’t affect other metals it comes in contact with, it is frequently used in a large array of applications, especially in piping and tubing manufacturing. Based on the end use of the pipe, stainless steel piping is broken down into several categories – Stainless Steel Tubing for General Corrosion-Resistance, Stainless Steel Pressure Pipe, Stainless Steel Sanitary Tubing, Stainless Steel Mechanical Tubing, Stainless Steel for Food Processing.

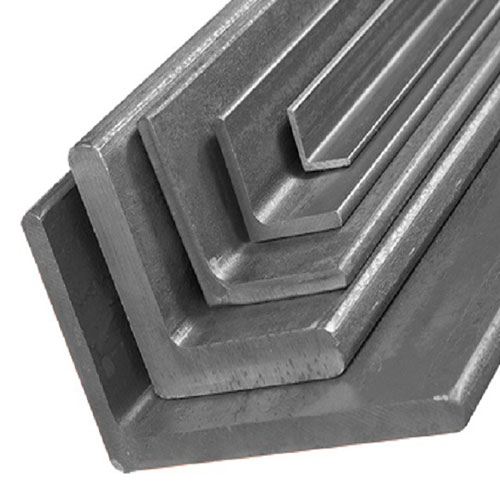

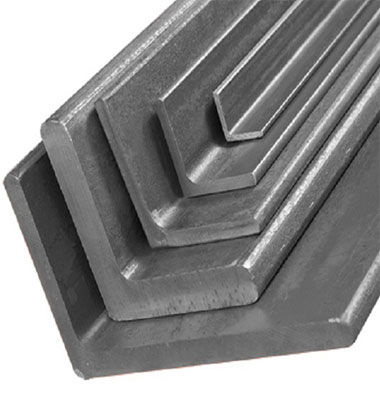

ANGLE BAR

In steel part fabrication and manufacturing, an angle bar is a type of bar used to create supported corners and outside rims. These corners and rims are used for various walls and surfaces. Such bars are easily applied to virtually any type of surface through welding or by using drilled fastening methods.

The steel angle bar, for example, is a steel bar shaped like an L. One angle is perpendicular to the other. This forms an inside angle as well as an outside angle. The sides of the angle often categorized as Equal Angle bar or Unequal Angle Bar.

Angle Bar Applications:

- Structural and Building Construction, Bridge Construction, Tanks, Pressure Vessel, Boiler and Heat Exchangers, Steel Supports, Steel Fabrications, Ship Building

Steel Grades:

- All grade range for Carbon Steel, Mild Steel, Boiler Plate Grade, Tanks, Ship Building, High Strength, Low-Alloy, we also have all range of Stainless grades.

Available Sizes:

- Thickness- 1.0mm to 30.0mm , Side- 15mm to 500mm, Length- 3,000mm to 12,000mm

BOLTS AND NUTS

A Steel Bolt is a mechanical fastener that is usually used with a nut for connecting two or more parts. A bolted joint can be readily disassembled and reassembled; for this reason bolts or screw fasteners are used to a greater extent than any other type of mechanical fastener and have played an important part in the development of mass-produced articles and steel structures.

The bolt consists of a head and a cylindrical body with screw threads along a portion of its length. The nut is the female member of the pair, having internal threads to match those of the bolt. Washers are often used to prevent loosening and crushing.

Common Bolt Types used in the Market:

- Anchor Bolt– Bolt designed to allow objects to be attached to concrete. The bolt head is usually placed in concrete before it has cured or placed before the concrete is poured, leaving the threaded end exposed.

- Hex Boltor Machine Bolt – Bolt with a hexagonal head and threaded body. Section immediately under head may or may not be threaded.

- J bolt– Bolt shaped like the letter J. Used for tie downs. Only the non-curved section is threaded for a nut to be attached.

- U Bolt– Bolt shaped like the letter U where the two straight sections are threaded. A straight metal plate with two bolt holes is used with nuts to hold pipes or other round objects to the U-bolt.

- Stud Bolt– a bolt with threads on both ends designed to be screwed permanently into a fixed part at one end and to receive a nut on the other.

Surface Finish Options:

- Bare, Black Oxide, Hot Dip Galvanized (HDG), Electric Galvanized, Plastic Coated, Special Paint

We have many sizes and specifications range available for any standard, like ASTM, ASME and many others.

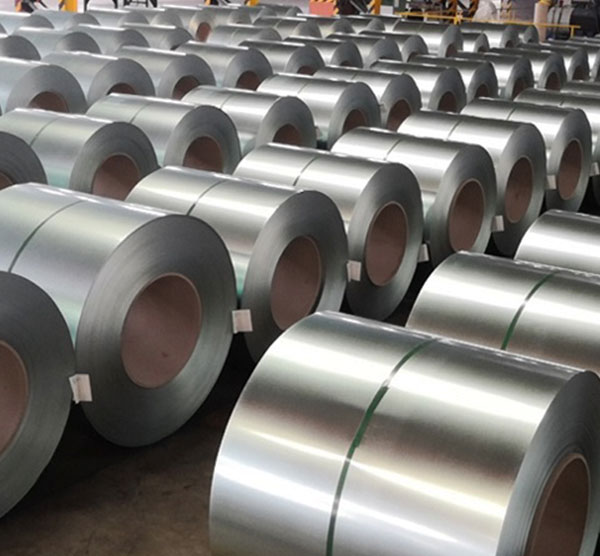

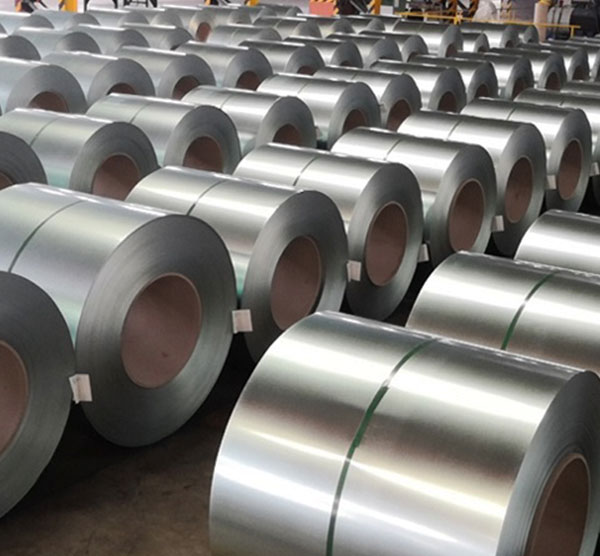

Steel Coil

is sheet metal supplied in coil form. Depending on the production method, such coil is classified as hot-rolled, cold-rolled, galvanised or polymer-coated . Steel coil is used across industry, the main consumers being the FOOD, Construction, and Machine-Building Sectors. We supply ALL TYPES, be it TIN FREE STEEL (TFS), ELECTROLYTIC TIN PLATE (ETP), GI, PPGI, ALUMINUM, or GALVALUME.

OTHER PRODUCTS

Gasket

Any types of Gaskets to seal mechanical fittings.

Insulation

Rock Wool, Glass Wool, Mineral Wool. We have Roll and Flat Bare, and Pre-Formed for steel pipes.

Copper Tube and Pipe

Sheet Pile

we have Type I, Type II, Type III, Type IV, Z-Type, U-Type. Hot Rolled and Cold Rolled are available.

Solar Street Lights

are raised light sources which are powered by solar panels generally mounted on the lighting structure or integrated into the pole itself. The solar panels charge a rechargeable battery, which powers a fluorescent or LED lamp during the night. We have 20Watts up to 300Watts available as commonly used.

Steel Coil

is sheet metal supplied in coil form. Depending on the production method, such coil is classified as hot-rolled, cold-rolled, galvanised or polymer-coated . Steel coil is used across industry, the main consumers being the construction and machine-building sectors. We supply ALL TYPES, be it ALUMINUM, TIN FREE STEEL (TFS), ELECTROLYTIC TIN PLATE (ETP) GI, PPGI, or GALVALUME.