In the Philippines, a nation surrounded by water, sea ports are lifelines for economic growth, trade, and connectivity. The development of robust and modernized sea ports requires durable materials to ensure the longevity and strength of port structures. Among these materials, spiral steel pipes stand out as key contributors. From enhancing port infrastructure to supporting the economy, spiral pipe piles and spiral welded pipes play an indispensable role in the country’s progress.

This article will explore how these steel solutions, supplied by industry leaders like Megalos Ferro Inc., are shaping the future of the Philippines’ maritime infrastructure.

The Importance of Sea Ports in the Philippine Economy

Sea ports are integral to the Philippines’ economy, facilitating the movement of goods, services, and people. As an archipelago, the country relies heavily on efficient port systems for:

- Trade: Ports handle approximately 98% of the nation’s import and export trade by volume.

- Connectivity: Ports connect remote islands, boosting inter-island commerce.

- Tourism: Ports enable the thriving cruise and ferry industry.

The growing demands of global trade necessitate upgrading these critical infrastructures, where spiral steel pipes come into play.

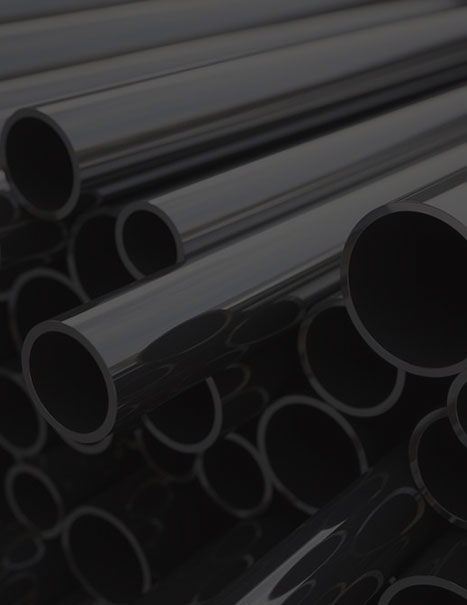

Why Spiral Steel Pipes Are Essential for Port Construction

Sea ports are exposed to harsh environmental conditions, including saltwater corrosion, strong waves, and heavy loads. The choice of construction materials is vital to ensuring durability and performance.

Spiral steel pipes are uniquely suited for sea port projects due to the following features:

- High Strength: Made from high-quality steel, spiral steel pipes can withstand substantial loads.

- Corrosion Resistance: Spiral welded pipes resist rust, ensuring longevity even in saltwater environments.

- Flexibility in Design: Their spiral structure allows for customization in length and diameter, catering to various port construction needs.

- Cost-Effectiveness: Spiral pipe piles are efficient to produce and install, reducing overall project costs.

With these advantages, spiral steel pipes are the backbone of marine infrastructure projects.

Applications of Spiral Steel Pipes in Sea Port Development

a. Foundations and Piling Systems

Spiral pipe piles provide a stable foundation for port structures, such as docks, piers, and jetties. Their structural integrity ensures that ports can support heavy cargo and withstand environmental stressors.

b. Underwater Pipelines

The corrosion-resistant properties of spiral welded pipes make them ideal for underwater pipelines used in fueling and water systems.

c. Breakwater and Coastal Reinforcements

Spiral steel pipes are used in constructing breakwaters and seawalls to protect ports from strong waves and prevent erosion.

d. Conveyor Supports

Modern ports rely on conveyor systems to transfer goods efficiently. Spiral steel pipes are employed as support structures for these systems, ensuring reliability and stability.

Megalos Ferro Inc.: Leading the Way in Spiral Steel Pipes

As one of the Philippines’ leading suppliers of spiral steel pipes, spiral pipe piles, and spiral welded pipes, Megalos Ferro Inc. is at the forefront of driving port development.

Why Choose Megalos Ferro Inc.?

- High-Quality Products: The company ensures the highest standards in manufacturing and sourcing.

- Custom Solutions: Megalos Ferro Inc. offers tailored pipe solutions to meet the specific needs of sea port projects.

- Sustainability Commitment: The company prioritizes eco-friendly practices in production and logistics.

Partnering with Megalos Ferro Inc. ensures reliable and durable materials for critical infrastructure projects.

Boosting the Philippine Economy Through Sea Port Development

The ripple effects of modernized sea ports extend beyond infrastructure:

- Job Creation: Port construction and operations generate thousands of jobs in the country.

- Improved Trade Efficiency: Ports equipped with spiral steel pipe-supported structures can handle larger volumes of goods, reducing costs and boosting competitiveness.

- Regional Development: Enhanced port infrastructure promotes economic growth in coastal and remote areas.

The use of spiral welded pipes ensures these benefits are built on a foundation of strength and durability.

Future Prospects: Sustainability and Innovation

As the world moves toward sustainable development, the use of eco-friendly materials and construction methods is becoming increasingly important. Megalos Ferro Inc. is committed to:

- Innovating with Green Steel: Developing steel products with reduced environmental impact.

- Supporting Circular Economy: Recycling and reusing materials to minimize waste.

- Adopting Smart Technologies: Leveraging advanced techniques for precise and efficient manufacturing of spiral steel pipes.

These efforts position the company as a key player in the future of Philippine infrastructure development.

read more