In the realm of construction, innovation is key to meeting the demands of modern infrastructure projects. Among the many advancements in construction materials, spiral welded pipe stands out as a versatile and efficient solution. Megalos Ferro Inc., a leading company in the field, has been pioneering the use of spiral welded pipe in construction projects, offering unparalleled advantages in terms of strength, durability, and cost-effectiveness.

What is Spiral Welded Pipe?

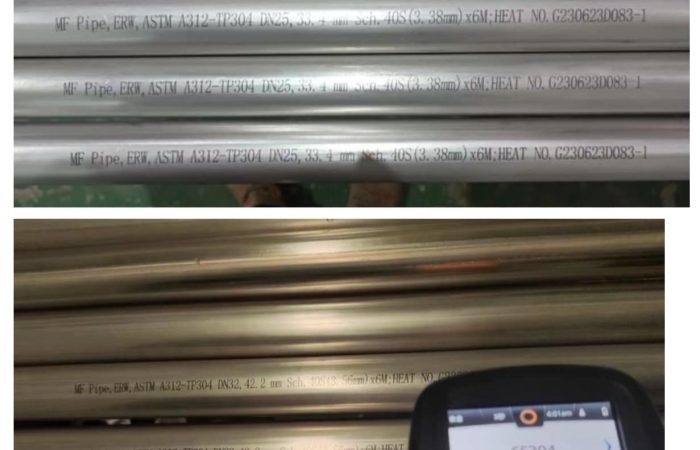

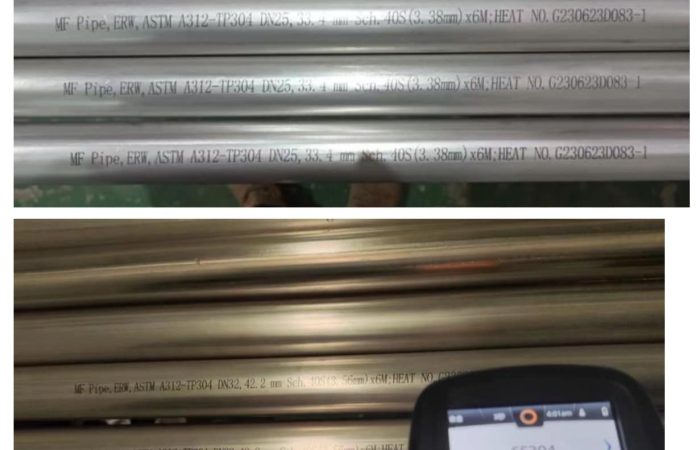

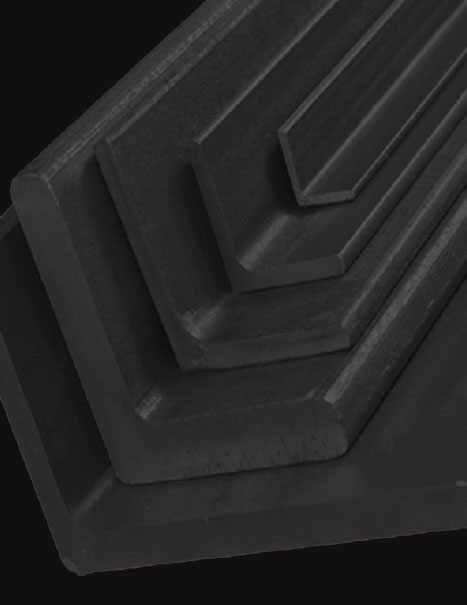

Spiral welded pipe is a type of steel pipe manufactured using a continuous helical weld. This unique production method results in a strong and flexible pipe that is well-suited for a wide range of applications in construction. Unlike traditional welded pipes, which are made from straight sections of steel, spiral welded pipe feature a seamless, spiral seam that provides superior strength and resistance to bending and deformation.

Advantages of Spiral Welded Pipe:

- Strength and Durability: The spiral welding process used in manufacturing spiral welded pipe results in a continuous, uniform weld that enhances the structural integrity of the pipe. This translates to greater strength and durability, making spiral welded pipe ideal for use in demanding construction environments where reliability is paramount.

- Flexibility: Due to its helical construction, spiral welded pipe offers greater flexibility compared to traditional straight-seam welded pipes. This flexibility allows for easier installation and reduces the need for additional fittings and joints, minimizing the risk of leaks and ensuring a more efficient construction process.

- Corrosion Resistance: Spiral welded pipe is often coated with protective coatings to enhance its resistance to corrosion, making it suitable for use in a variety of harsh environments, including underground applications and corrosive industrial settings. This corrosion resistance extends the lifespan of the pipe, reducing maintenance costs and enhancing the overall longevity of the infrastructure.

- Cost-Effectiveness: Despite its advanced manufacturing process and superior performance characteristics, spiral welded pipe remains a cost-effective solution for construction projects. Its durability and longevity reduce the need for frequent replacements and repairs, ultimately saving both time and money over the lifespan of the infrastructure.

Megalos Ferro Inc.: Leading the Way in Spiral Welded Pipe Technology

Megalos Ferro Inc. has established itself as a pioneer in the field of spiral welded pipe manufacturing, leveraging cutting-edge technology and decades of expertise to deliver innovative solutions to the construction industry. By continuously pushing the boundaries of what is possible with spiral welded pipe, Megalos Ferro Inc. has earned a reputation for excellence and reliability among contractors, engineers, and developers worldwide.

Spiral welded pipe offers a host of advantages that make it an indispensable component of modern construction projects. From its superior strength and durability to its flexibility and cost-effectiveness, spiral welded pipe provides a versatile and reliable solution for a wide range of applications. With Megalos Ferro Inc. leading the way in technological innovation and expertise, the future of spiral welded pipe in construction looks brighter than ever.

read more