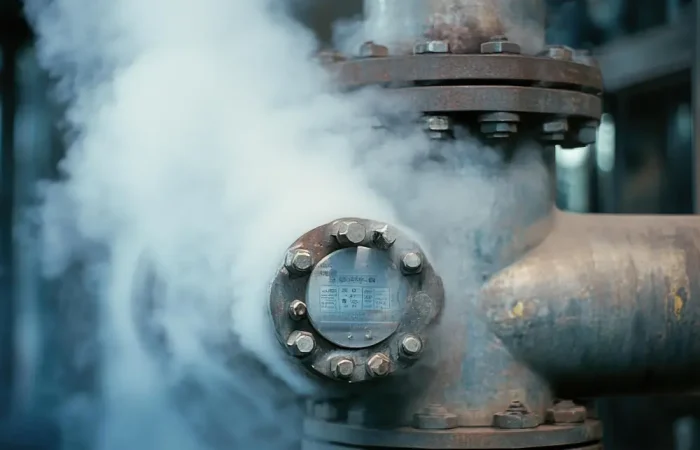

Flooding during monsoon seasons poses significant challenges to urban and rural infrastructure, safety, and the economy. To effectively manage excess water and prevent devastating floods, reliable and durable piping solutions are essential. Among these, Spiral Welded Pipe has emerged as a critical component in flood prevention systems worldwide. Megalos Ferro Inc. specializes in manufacturing high-quality Spiral Welded Pipes that meet the demands of modern infrastructure projects.

Understanding Spiral Welded Pipe: An Overview

Spiral Welded Pipe is a type of steel pipe manufactured by forming steel sheets into a spiral shape and welding the seams longitudinally. Its unique manufacturing process results in a pipe that offers superior strength, flexibility, and durability, making it ideal for various applications, including flood management.

Key Features of Spiral Welded Pipe

- High Tensile Strength: The spiral welding process enhances structural integrity, enabling the pipe to withstand high water pressures during monsoon floods.

- Corrosion Resistance: When coated or galvanized, Spiral Welded Pipes resist rust and corrosion, extending their lifespan in harsh environmental conditions.

- Flexible Lengths and Sizes: Available in a wide range of diameters and lengths, making them adaptable for different flood control projects.

- Cost-Effectiveness: The manufacturing process allows for economical production without compromising quality.

Why Spiral Welded Pipe Is Essential for Flood Prevention

Flood prevention infrastructure must withstand extreme water flows, debris, and environmental stressors. Spiral Welded Pipe offers several advantages that make it an optimal choice for such applications.

1. Superior Structural Strength

During heavy monsoon rains, water flow can exert immense pressure on drainage systems and culverts. Spiral Welded Pipe’s high tensile strength ensures that these pipes can handle such pressures without failure, minimizing the risk of blockages or collapses.

2. Enhanced Durability in Harsh Conditions

Floodwaters often carry debris, mud, and chemicals that can accelerate corrosion. Spiral Welded Pipes, especially when galvanized or coated, resist corrosion, ensuring long-term performance vital for flood mitigation.

3. Adaptability for Large-Scale Flood Control Projects

Large-scale flood control projects require pipes that can be customized in size and length. Spiral Welded Pipe’s flexibility in manufacturing makes it suitable for constructing extensive drainage networks, retention basins, and flood barriers.

4. Ease of Installation and Maintenance

The modular nature of Spiral Welded Pipe simplifies installation, reducing project timelines and costs. Its durability also minimizes maintenance needs, ensuring continuous flood protection during monsoon seasons.

Applications of Spiral Welded Pipe in Flood Prevention

Spiral Welded Pipe is versatile and highly applicable in various flood management systems, including:

1. Drainage Systems

Proper drainage is crucial in preventing urban flooding. Spiral Welded Pipes are used to construct stormwater drainage channels that efficiently channel excess rainwater away from populated areas.

2. Culverts and Underpasses

For roads and bridges, spiral welded pipes form culverts that allow water to pass underneath infrastructure safely, preventing water accumulation and flooding.

3. Flood Barriers and Levee Foundations

In some cases, Spiral Welded Pipes serve as foundational elements in constructing flood barriers and levees, providing structural stability against rising water levels.

4. Retaining Walls and Water Retention Structures

These pipes are also used in building water retention structures that help control and direct floodwaters during heavy rains.

The Role of Megalos Ferro Inc. in Providing Quality Spiral Welded Pipes

Megalos Ferro Inc. is a leading manufacturer specializing in high-grade Spiral Welded Pipe solutions tailored for flood prevention and infrastructure projects. With advanced manufacturing facilities and a commitment to quality, Megalos Ferro Inc. ensures that every Spiral Welded Pipe meets international standards.

Why Choose Megalos Ferro Inc.?

- Quality Assurance: All pipes undergo rigorous testing for strength, durability, and corrosion resistance.

- Custom Solutions: We offer customized sizes and specifications to fit project requirements.

- Timely Delivery: Our efficient supply chain ensures timely availability of Spiral Welded Pipes.

- Competitive Pricing: We provide cost-effective solutions without compromising on quality.

Benefits of Using Spiral Welded Pipe for Flood Management

Implementing Spiral Welded Pipe in flood prevention infrastructure offers multiple benefits:

- Long Service Life: Resistant to environmental factors, ensuring durability over decades.

- High Load-Bearing Capacity: Suitable for large-scale and heavy-duty applications.

- Ease of Fabrication: Can be manufactured in various sizes and shapes to suit specific project needs.

- Eco-Friendly Construction: Recyclable materials and eco-conscious manufacturing processes.

Challenges and Considerations in Using Spiral Welded Pipe

While Spiral Welded Pipe offers numerous advantages, certain factors must be considered:

- Proper Coating and Maintenance: To maximize corrosion resistance, proper coating and periodic maintenance are essential.

- Design Compatibility: Ensuring the pipe size and specifications align with project demands is critical for optimal performance.

- Installation Expertise: Skilled installation ensures the pipe’s structural integrity and long-term functionality.

Future Trends: Innovations in Spiral Welded Pipe for Flood Prevention

Advancements in manufacturing technology continue to improve Spiral Welded Pipe quality. Innovations include:

- Advanced Coatings: Development of more durable anti-corrosion coatings.

- Smart Pipe Systems: Integration of sensors for real-time monitoring of water flow and pipe integrity.

- Sustainable Materials: Use of eco-friendly and recycled materials to reduce environmental impact.

Flood prevention during monsoons is a vital aspect of safeguarding communities, infrastructure, and the environment. Spiral Welded Pipe plays a pivotal role in developing resilient drainage systems, culverts, and flood barriers. Its strength, durability, and adaptability make it an ideal choice for large-scale flood mitigation projects.

Megalos Ferro Inc. stands at the forefront of manufacturing high-quality Spiral Welded Pipes that meet the rigorous demands of flood prevention infrastructure. By choosing Spiral Welded Pipe from Megalos Ferro Inc., governments, contractors, and engineers can ensure reliable, long-lasting flood protection during the challenging monsoon seasons.

read more